Taking off underground: mine inspection with 3D models

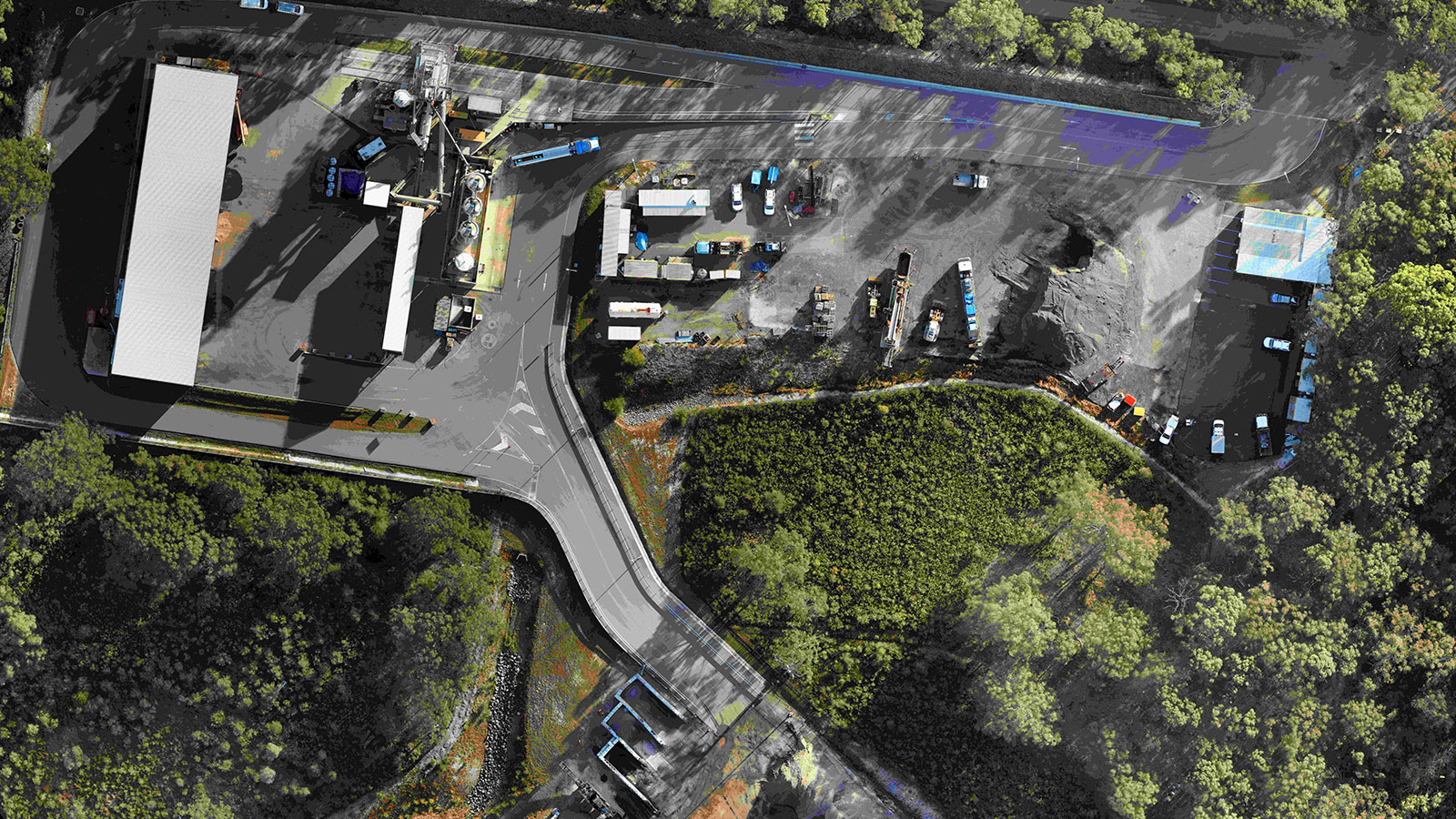

The benefits of drones in the mining industry have been proven again and again in opencast mines.

But underground mines present a unique set of challenges.

The narrow passageways - sometimes barely wider than a person’s shoulders - make it impossible to fly.

A unique new drone can offer a solution.

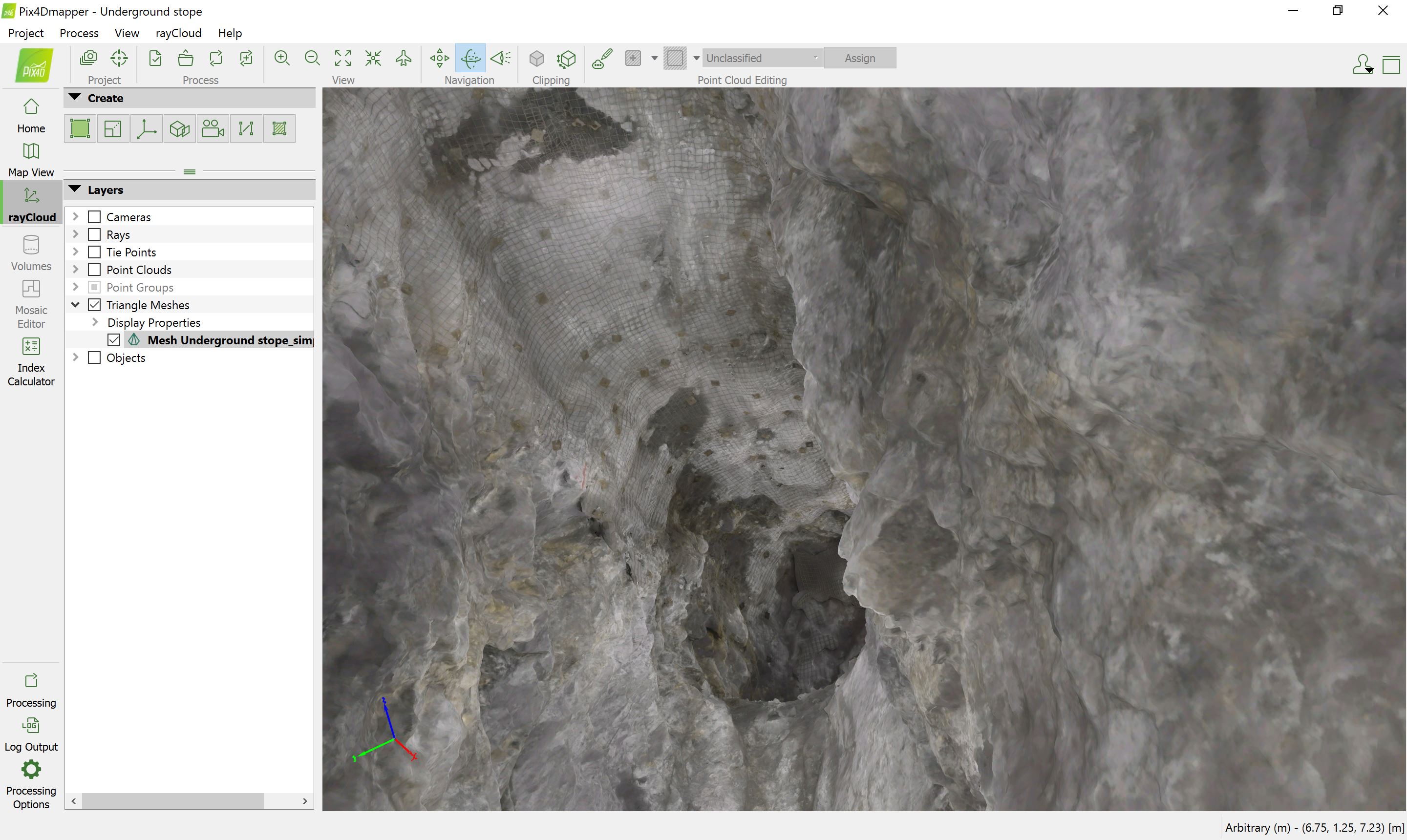

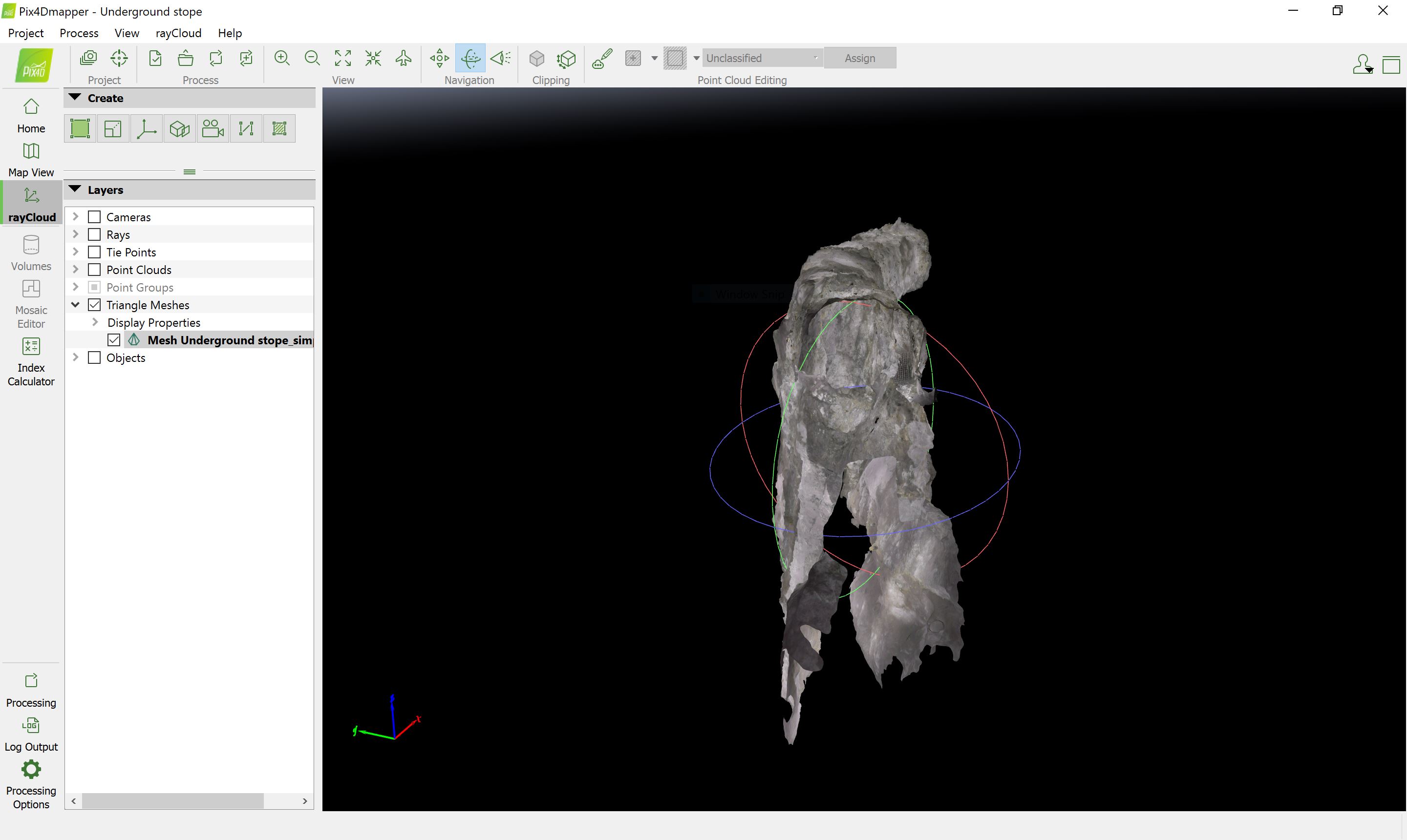

The Elios 2 drone from Flyability flew successfully even in confined shafts less than three meters in diameter. Images from the drone were processed in Pix4Dmapper.

Project details

| Location | Golden Sunlight Mine Montana, United States |

| Mining company | Barrick Gold |

| UAV operators | Unmanned Aerial Services Ltd |

| Hardware | Elios 2 drone from Flyability |

| Software | Pix4Dmapper |

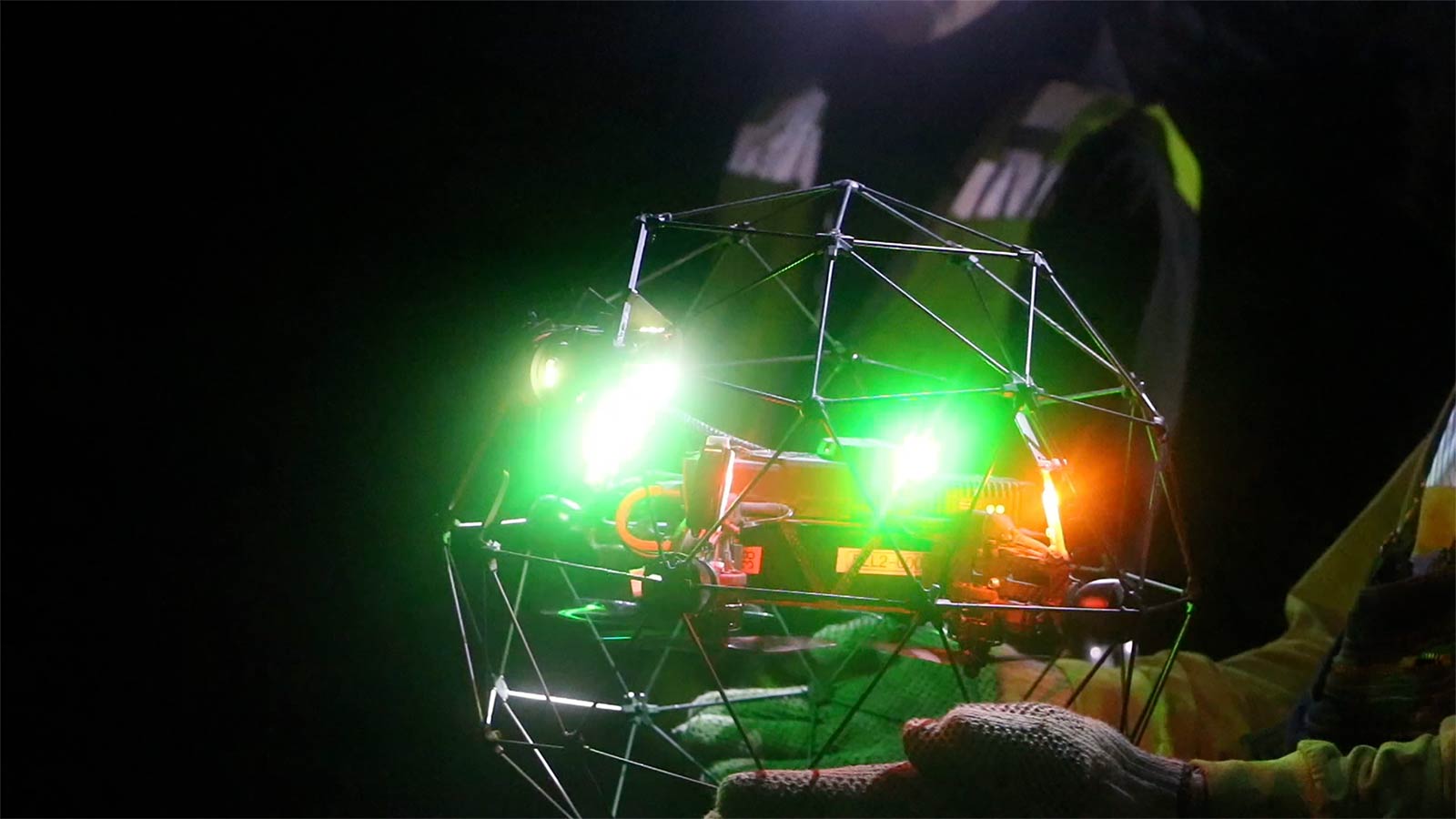

Elios 2 drone: unique hardware for dangerous environments

Flyability’s Elios 2 drone is created specifically for confined spaces. The rotary drone is surrounded by a framework which can be bumped into walls, infrastructure, and even people without causing any harm to equipment or personal. It’s designed to go places where a normal drone simply can’t.

Ryan Turner, Geotechnical Engineer for Barrick Gold Corporation commented: “A year ago I would have said this wasn’t possible… we’ve lost a lot of drones underground. For us to have five drones underground in the last three days and to not lose any of them - that’s really saying something.”

Read more about the hardware on Flyability’s blog.

Mapping in the underground mining industry

Inspection is vital in underground mines.

After blasting rocks and minerals, loose material remains behind and can slip without warning. With rocks as large as a small car balanced precariously on a stope, it’s essential that personnel have an overview of the site.

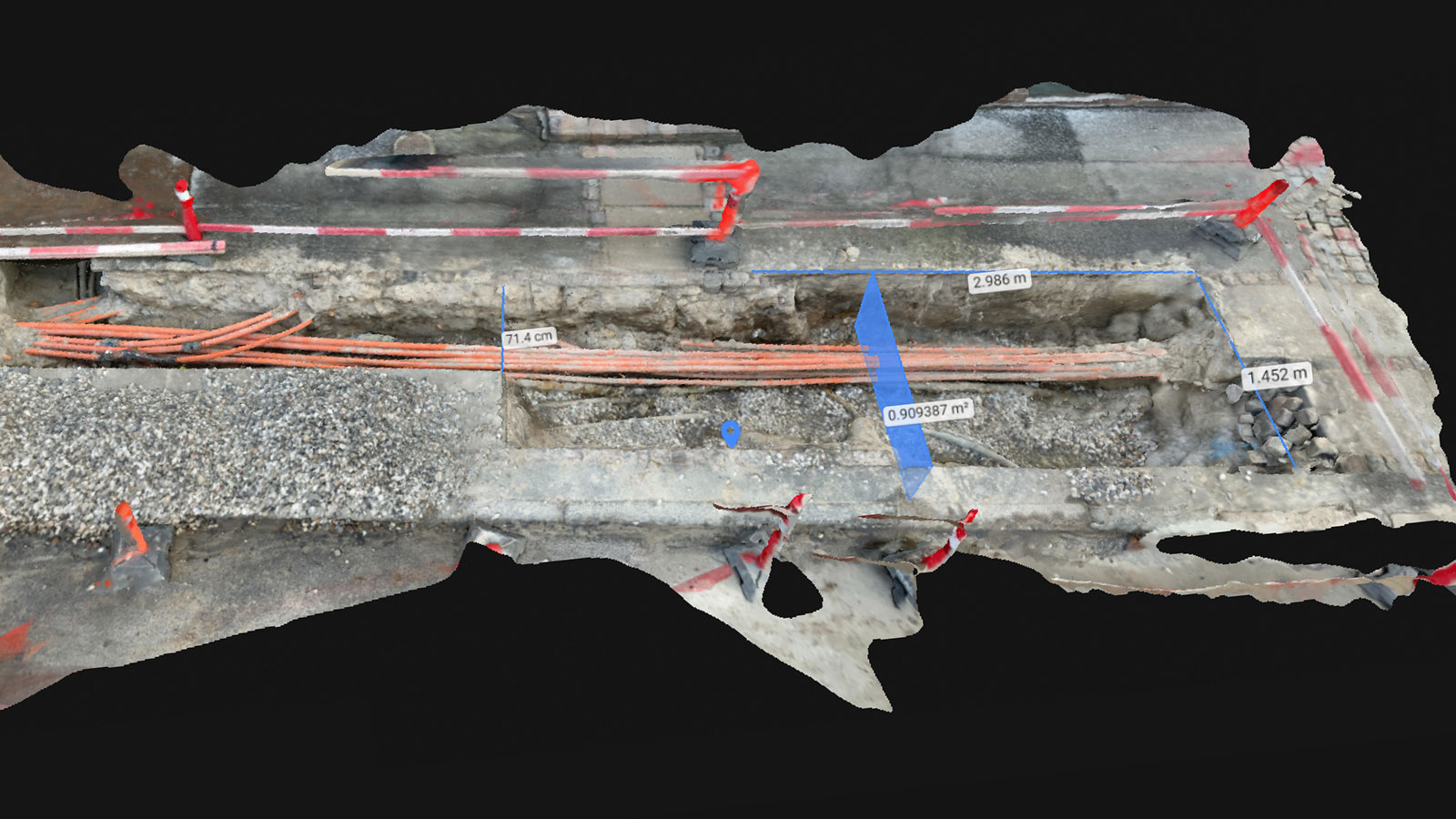

Traditional inspection methods involve lowering a camera or inserting it into the area on a pole. However, these methods are limited and do not provide the full picture.

Turner explains: “My job is to make sure that the underground workings are stable and they don’t fall down on the miners... the main challenges are going into these areas where we don’t have very much information and trying to figure out if they’re stable or if they are going to cause problems - possibly release material onto our equipment or onto our miners.”

As well as danger to personnel, shifting material is hazardous to mining equipment: each machine costs upwards of a million dollars and can be destroyed by a slip.

Finally, waste material can dilute valuable ore, or cause it to be missed entirely, impacting the bottom line.

In order to avoid these issues, the Barrick Gold Corporation wanted to create a detailed 3D photogrammetric map of a stope.

Turner describes the process: “We flew into a stope we wanted to investigate how much overbreak had occurred… when we flew with the Elios 2, we were able to see a lot of the structures that are releasing material. Particularly on the western rib where a large slab had come out.”

The next day, the flight was repeated, as material can shift over time and as adjacent areas are blasted. By comparing the two photogrammetric models, the team can see where overbreak has occurred, and calculate the danger to miners, the risk to equipment and potential loss of ore.

Accurate results for a safer working environment

Drones in mining are often used to calculate stockpile volume, but in this case a visual inspection was just as important as taking measurements - something that was available with the Elios 2’s live feed.

Turner commented: “With the Elios 2 we were able to see where the structures were releasing material. The imagery looked really good.”

Back above ground, the team loaded the data from the Elios 2 into Pix4Dmapper.

The team did not work with ground control points as the stope’s relative accuracy was more important.

Using the 3D model created in Pix4Dmapper, Turner and the Barrick Gold team were able to make more informed decisions about their work in the mine, and identify any potential hazards.

Turner recalls: “We were able to see if there was any loose material directly above the mucker (rock moving machine) that could potentially release and cause damage to the mucker... We could show that footage to the operator and show him what was going on above him.”

As well as allowing Turner and the team a better overview of the mine, 3D models provide a record of the mine, and can create valuable learnings for the future as rockfall can be accurately tracked after a blast.

A full 3D inspection of the difficult to access underground mine means safer working conditions for the miners, and a positive impact on the company’s bottom line.

This first-of-its-kind use case also has wider implications for industries beyond mining and aggregates as the Elios 2 and Pix4Dmapper open up new horizons.