Inspecting telecom assets installed on water towers

Telecom assets come in all shapes and sizes, and not all have to be mounted on telecom towers. You’ll find them disguised in artificial trees, on top of buildings, or, in the case of France, on top of water towers. There are 16,000 water towers (or chateaux d’eau) in France.

The designs of water towers vary, with some looking like medieval castle towers or with more modern styles, but they are typically tall and located near urban settlements. Water towers are however not designed to host antennas which is a challenge for telecom operators and an additional reason to have their assets digitized.

Recently, Instadrone was asked to digitize and inspect assets mounted on a water tower. The client, Illiad, one of the major telecom operators in France, had no previous records of the structure and therefore needed accurate, comprehensive 3D model to learn what equipment is present on the tower, if there is any space left for installing new equipment, and to better plan future maintenance work.

Instadrone is a drone service provider working across France offering inspections, agricultural services, communication, surveying, and topographic analysis. Founded in 2014 by Cédric Botella, the company is investing energy and resources into asset and infrastructure inspections with drones. They see it as a growing industry that will benefit from using drone inspection solutions. They want to streamline telecom tower inspections with drones to provide an end-to-end workflow that includes everything from data capture to data analysis.

Project details

| Company | Instadrone |

| Location | Tabanac, France |

| Software | PIX4Dinspect |

| Hardware | DJI Matrice 300 RTK and P1 camera |

| Number of images captures | 350 (overdensified for better quality) |

| Data capture duration per tower | 60 minutes |

| Tower height | 30 meters |

Digitizing a water tower

For this project, the flight aim was to gather data about the tower and the telecom equipment for the client. The client had no records of the tower as they were renting space on it and needed up-to-date information of the assets to know their condition to plan maintenance works, remove old equipment and install new assets on the site.

The Instadrone pilot used an M300 drone, which is a multirotor model. This multicopter design is the best style of hardware for telecom inspections because it is more maneuverable and can capture the sides and angles of a static object better. The M300 was mounted with the Zenmuse P1 camera. This modern camera is often used by Instadrone because of the high resolution it provides. The data captured with this drone was uploaded to PIX4Dinspect, and the digital twin had a high level of detail with 1 centimeter per pixel. This accuracy is ideal for inspections because it means even small faults can be detected with just drone imagery.

Automatic tower inventory thanks to AI algorithms

Thanks to the machine learning and artificial intelligence behind PIX4Dinspect, it provides a scalable solution that can be replicated on different sites. This is partly due to the asset inventory that it provides. The software automatically recognized all ancillary boxes, panel and microwave antennas that were present on the water tower, including their dimensions (azimuth, downtilt, plumb, and height). This saved Instadrone a lot of time that they would have spent manually identifying each asset from the images they captured.

Analyzing the tower and assets condition with PIX4Dinspect

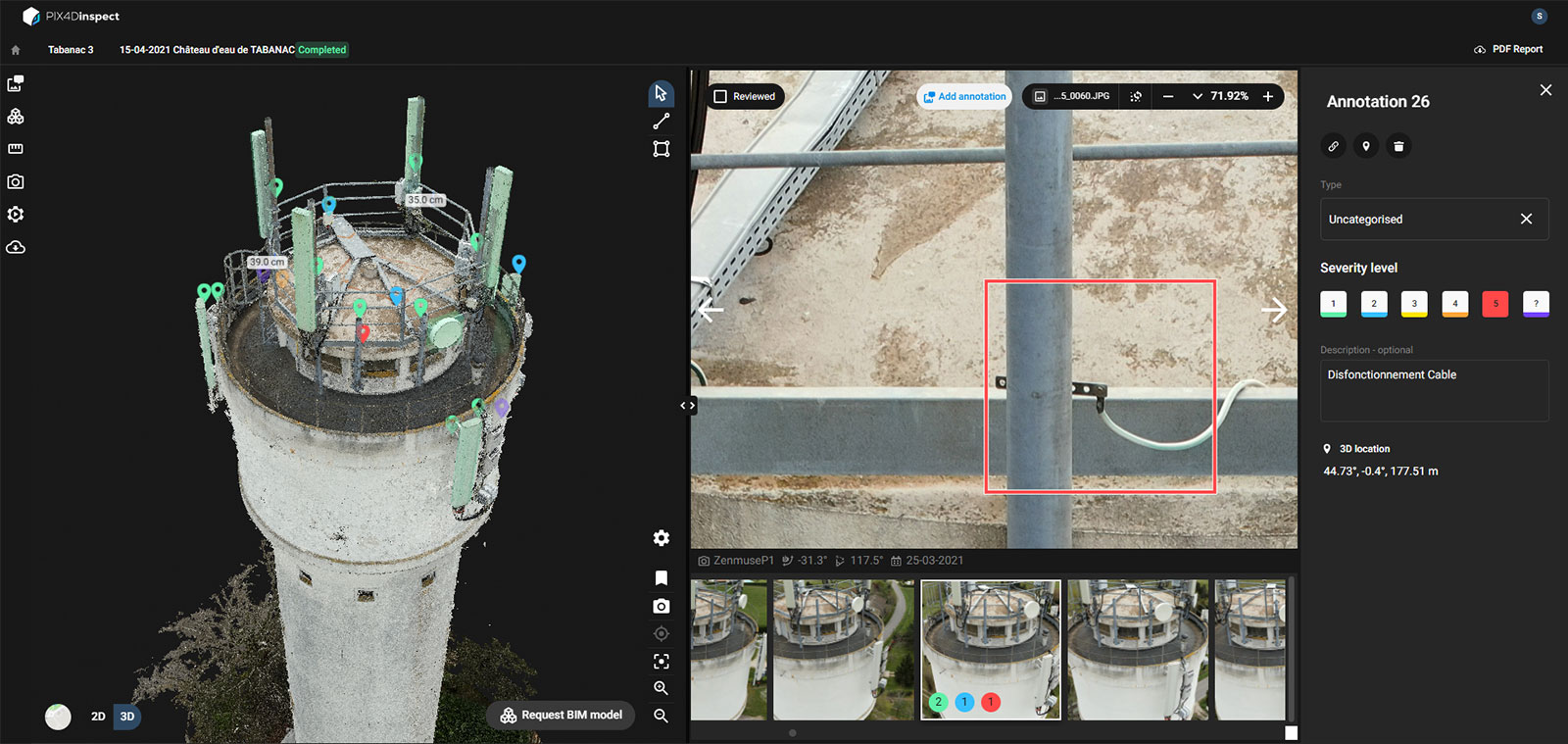

Alongside the automated inspection with AI, the Instadrone team conducted their own analysis of site using the digitzed water tower on PIX4Dinspect. They checked and marked all equipment according to its conditions by assigning a severity level to determine what required immediate action. The faults identified included cracked concrete, or missing caps. They also identified missing nuts and bolts, a disfunctional cable, as well as rust.

By looking at the model and analyzing the faults, the Instadrone team could check what objects were in working condition and what needed attention. The annotations and severity catalog were used to create an automatic pdf report from PIX4Dinspect that was shared with the technicians and the client, which showed the exact location of faults, their status, and recommended actions. This streamlined communication prevented any potential confusion over the water tower’s status.

Having all the important information in one place

The pdf report from PIX4Dinspect, as shown by Instadrones here, includes an inventory of the all the items. They are listed along with their dimensions and a photo that is automatically selected by the AI. All the annotations can be seen, including measurements, relevant photos, and the severity level. This is the report that was sent ot the client and technician team, keeping everyone up-to-date with the progress of the site.

Full service: from data capture to data analysis

Instadrone provided a full service to the client from capturing the tower with their drone operators to creating a digital twin of it and its assets, and analyzing it. Their engineers identified areas which required immediate actions thanks to the PIX4Dinspect sofware. Instadrone successfully proved the value of their services, which culminated in further work with this client.