Smart inspection of a solar farm using drones

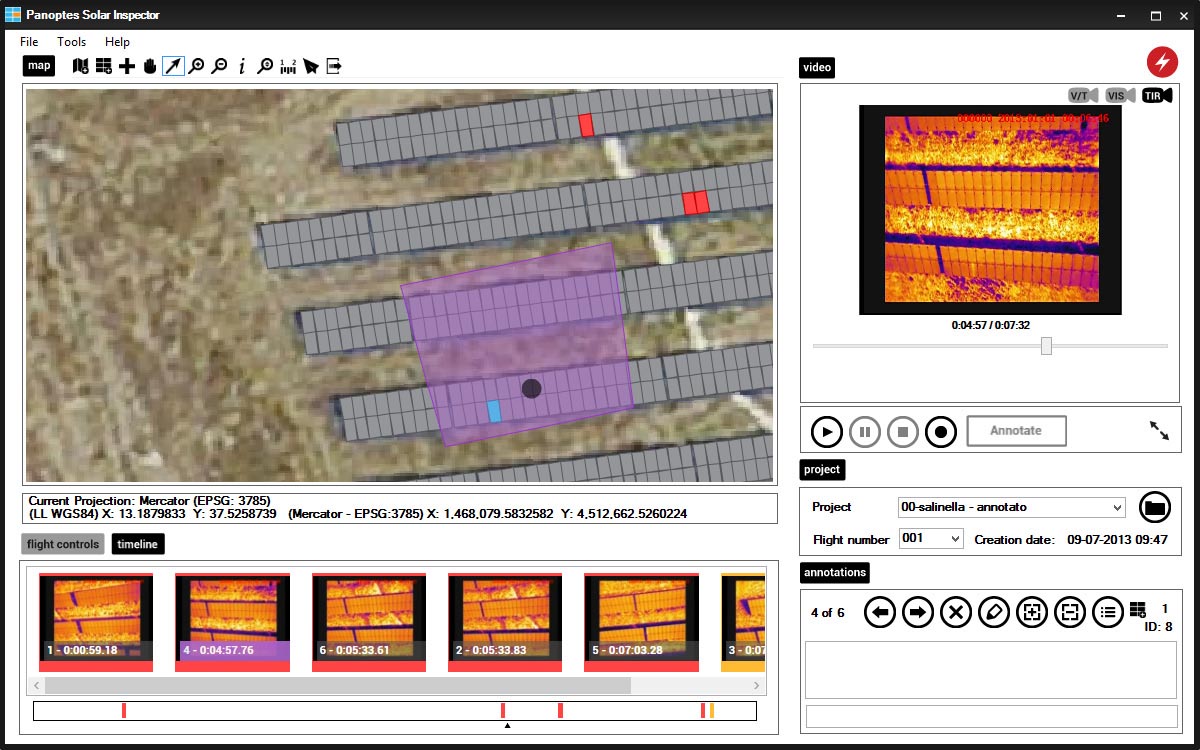

French renewable-energy producer Akuo Energy, hoping to increase detection of damage and hotspots in their solar panels, hired aerial surveillance company Air-Marine to evaluate the efficiency of their solar fields.

Regular inspection of the photovoltaic panels ensures that any defects with the potential to cause a reduction in solar power yield are quickly found and repaired.

The solar farm chosen by Akuo is located in France and stretches over 330 hectares of land, with an installed power capacity of 24 megawatts produced by more than 75,000 solar modules.

| Company | Akuo Energy |

| Country | France |

| Industry | Inspection |

| Project date | June 2015 |

| Project members | Air-Marine |

| Project Size | 66 Hectare |

| Number of images | 370 |

| GSD | 2.8 cm |

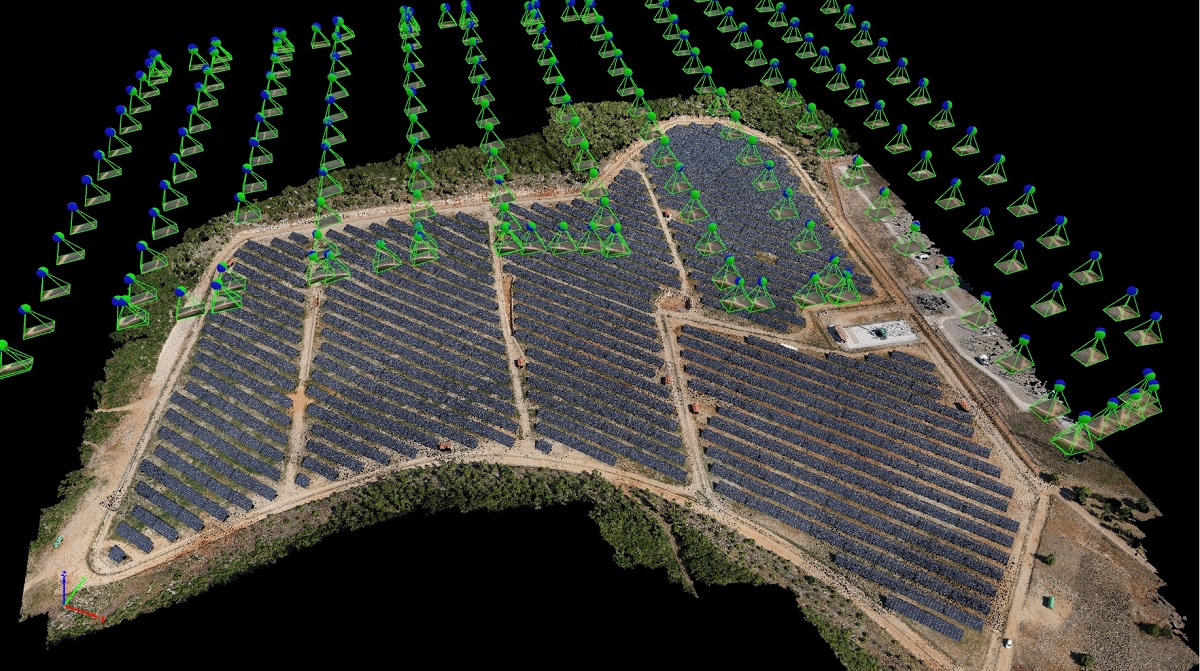

In order to inspect a large surface area like this solar field, a drone needs to be highly reliable and be able to fly relatively long periods of time without stopping or running out of battery. For this project, a Microdrones MD4-1000 vertical takeoff and landing drone was chosen, with a flight time of up to 88 minutes and payload of 1.2 kilos.

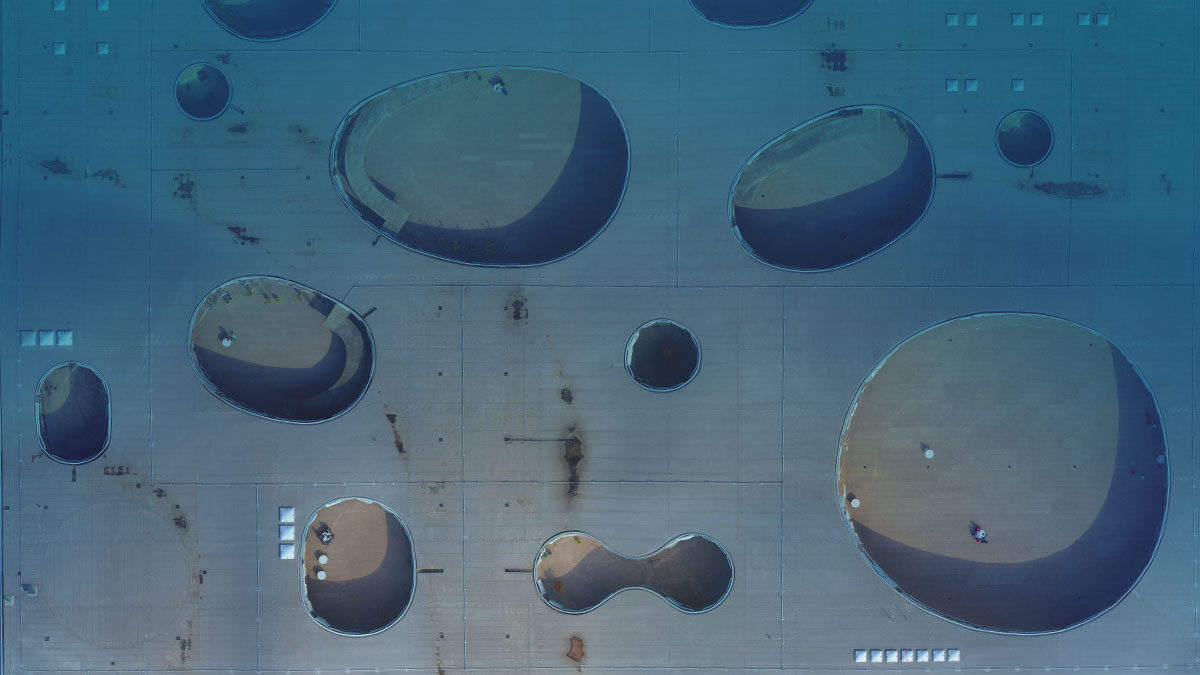

Images from the Sony Alpha 7 (370) were processed in Pix4Dmapper, along with five fixed ground control points (GCPs) at 2 cm accuracy, to produce a georeferenced true orthomosaic of the solar field at 3 cm GSD. The orthomosaic was then digitized to create vector drawings (shapefiles) of the solar panels, which served as a base map for the final report.

Quicker inspections. Increased efficiency.

Akuo had previously been inspecting their solar panels individually, using a handheld infrared camera. For each annual inspection, this took two employees around four days of work: walking through the farm and capturing an image of each panel.

This drone inspection was carried out in two days, with two operators in the field and one geomatics expert doing post-processing. For Akuo this means in the first year alone, a 50% reduction in time spent on site by field technicians and a 30% reduction in time spent post-processing the IR images.In the end, having lower inspection costs enable a company to increase the effectiveness and number of yearly inspections, which could be especially relevant in the cases of operation and maintenance contracts linked to plant efficiency.